|

Silverback |

|---|

Working across industrial workplaces, workshops and warehouses, proper spill control measures are a huge factor in both work health and safety (WHS) and efficiency — not to mention it's a legal requirement to have compliant measures in place.

This may sound like an abstract and technical issue; however, many of these same principles are the ones we face at home. Dangerous chemicals are not exclusive to industrial environments and are often found in household cleaning products that anybody can buy at the grocery store.

It is essential that everyone is aware of the chemicals they use so they can be best prepared for spills, both in the workplace and in day-to-day life.

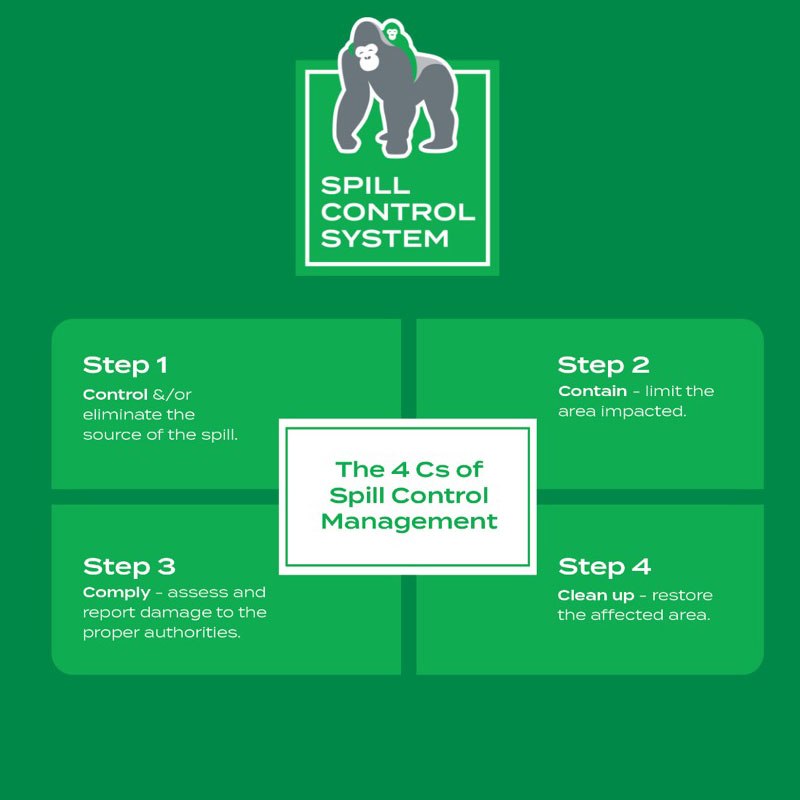

There is no doubt, however, that industrial environments that work with huge volumes of liquids will need some specialist tools. This is why Silverback has created the Spill Control System — comprising the 4 Cs (to be explained) and utilising their specialist spill kits.

If your workplace deals with large quantities of hazardous liquid regularly, then the potential for spills are an unfortunate reality you must be wary of. No matter how much effort you put into preventing spills, the proper process must still be in place to deal with one when it occurs.

Spills can come from a range of sources, such as ruptured drums, leaking pipes or taps, vehicles, valves, and generators. They can be slow or fast and involve a variety of different substances. This brings us to our first point: Each spill must be assessed and dealt with differently.

Before we begin our 4 Cs, there is step zero. This is an essential step that must take place before any work even begins. Step zero is that everyone working around these liquids must be sufficiently educated and aware of the substances they are working with and the best practices for dealing with spills. This is not only a WHS issue but also a legal necessity.

Clear signage can be a helpful aid, but in the moment of a spill, workers do not have time to read and learn — they must be aware of the best practices before a spill happens, and it is not enough to simply display signage and have one spill kit.

Working with acids and other hazardous chemicals can be extremely dangerous, and a worker who attempts to clear a hazardous spill must follow specific practices or be exposed to injury. Businesses are legally obliged to have appropriate measures in place and ensure staff are aware of chemical types.

It’s important to note that awareness is not just about substance types but also other factors, such as concentration, as this can determine whether it is safe.

Getting the most out of a spill kit means choosing the right one for the job. Using the wrong spill kit can be disastrous. With this in mind, Silverback's expert team has developed a spill kit selector chart to guide your choice for varying applications.

Once step zero has been integrated, the 4 Cs provide a solid plan of action:

Step 1 is all about staying in control. While any spill is unfortunate, how you deal with it is key. How you proceed will differ significantly based on step zero. Assess the spill and consider if it is safe to proceed or if you must evacuate and call the emergency services.

Never try to deal with it if you’re in any doubt. Even clear, seemingly safe liquids can be dangerous chemicals. These can also give off hazardous fumes.

If it has been established that the spill is safe to deal with, the priority is to eliminate the source of the spill. Again, this will differ depending on the circumstances. If a drum has fallen onto its side and spilt, eliminating the source can be as simple as rolling it into a position where it is no longer leaking. If a container has been punctured, there are temporary repair putties available that can be used to plug a leak quickly. If a container has been completely destroyed, eliminating the source may not be possible, and you will proceed straight to step 2.

Step 2 is about limiting spills' spread and preventing them from cascading to vulnerable areas.

Vulnerable areas are typically drain openings or natural water channels — anything that will carry the spill offsite and cause an environmental problem. However, it can also involve areas where the spill is incompatible with another substance (certain chemicals are volatile when combined with other materials).

To limit this spread, the vulnerable area must be identified quickly. As part of step zero, it is always better to be aware of sensitive areas so you can immediately act when a spill occurs.

A spill can be lassoed to prevent it from reaching the vulnerable area. Lassoing includes intercepting the body of fluid as it moves by creating a dam, optimally with booms, a vital Silverback Spill Kit range component. Even with the best equipment, this can be a challenge, depending on the speed of the liquid flowing down the surface gradient. Therefore, it's best to prioritise any vulnerable areas and move quickly to protect those rather than the general spread of the spill.

Once a spill has been contained, step 3 covers the assessment, clean up and any compulsory reporting. If you cannot properly contain a spill that has gone down the drain, you must report it to a local environmental protection authority or the government responsible for drainage.

When it comes to step 4, the process depends on the spill type, its size, and the surface it is on. Regardless, try to deal with it promptly. You can deal with some spills internally by pouring and raking around loose absorbents. For porous surfaces such as soil or grass, your options are limited. You can dig affected soil out and bag it for disposal. This will be hazardous waste and will need to be disposed of properly.

For large spills you cannot deal with internally, you can hire sucker truck organisations to come and remove the waste for you.

Don't miss out on Silverback’s limited deal! Until the end of September 2023, you'll get a Free Site Assessment and Free Toolbox Training when you place spill kit orders over $1000.

This opportunity is available for up to 25 members of your team. You'll boost workplace safety and stay compliant by giving your employees the necessary skills and equipment.

Learn more here.