|

Silverback |

|---|

Ensuring safe loading of vehicles is of utmost importance in preventing injuries, cargo damage, and property damage. Using appropriate load restraint equipment and techniques can result in significant safety and economic benefits. When the cargo arrives at its destination without damage, it saves time and money. The information provided in this blog is based on proven principles of load restraint and the ability of load restraint equipment to apply the necessary forces for the safe transportation of goods.

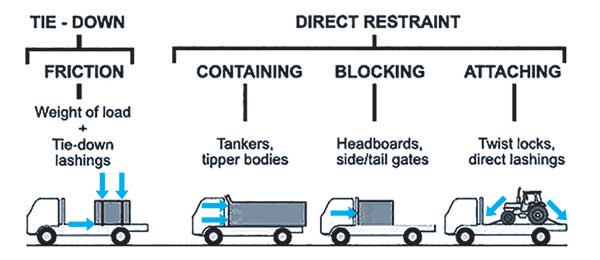

Choose the most suitable restraint method, given your load and vehicle. Loads can be restrained by two primary methods: tie-down or direct restraint (i.e. containing, blocking, and attaching). The following diagram shows the different restraint methods for controlling load movement in the forward direction. The same principles apply to backward and sideways movements.

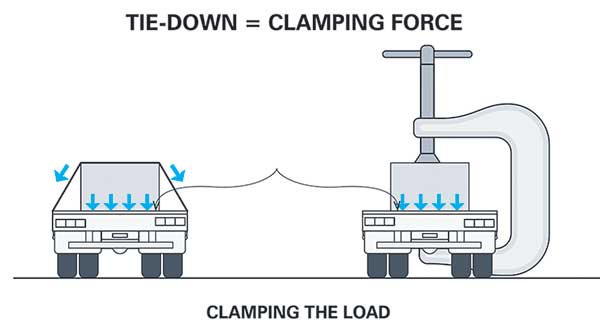

Under this method, friction stops the load from moving forward, sideways, and backwards. Friction force comes from the load's weight and the clamping force of tie-down lashings. The weight of the load alone does not provide adequate restraint. For tie-down to be effective, the load must be in contact with the vehicle throughout its journey. Tie-down lashings clamp the load to the vehicle to maintain friction.

Friction can be significantly reduced by:

Tie-down lashings include straps and chains. These typically pass over the top of a load and are attached to the vehicle on both sides. Tie-down lashings need to be pretensioned to create the clamping force, typically done using mechanical tensioners suitable for the lashing you are using. When a load is tied down and restrained using friction, it must also be restrained vertically to withstand a minimum force of 20% of its weight (i.e. 0.2W); this stops it from shifting upwards (e.g. on rough roads) and keeps the load in contact with the vehicle throughout its journey.

Some loads are unsuitable for tie-down restraint. These include:

The friction between the load and deck surfaces (and any surfaces in between) will affect how much weight each lashing can restrain. The greater the friction, the more weight each tie-down lashing can restrain.

Typical friction levels for common loads are outlined below:

| LOAD | FRICTION |

| Wet or greasy steel on steel | VERY LOW |

| Smooth steel on smooth steel | LOW |

| Smooth steel on rusty steel | LOW TO MEDIUM |

| Smooth steel on timber | MEDIUM |

| Smooth steel on a conveyor belt | MEDIUM |

| Rusty steel on rusty steel | MEDIUM TO HIGH |

| Rusty steel on timber | HIGH |

| Smooth steel on rubber load mat | HIGH |

The pretension achieved in a lashing will also affect the lashing capacity. The greater the pretension, the more weight that each lashing can restrain. The table below lists examples of average pretension that different tensioning items can achieve. However, knowing what tension you can get with your equipment is essential.

| LASHING SIZE (mm) | TENSIONER | PRETENSION FORCE (kg) | |

| Rope | 10 | Single Hitch | 50 |

| 12 | Double Hitch | 100 | |

| Webbing | 25 | Hand Ratchet | 100 |

| 35 | Hand Ratchet | 250 | |

| 50 | Truck Winch | 300 | |

| 50 | Hand Ratchet (push up) | 300 | |

| 50 | Hand Ratchet (pull down) | 600 | |

| Chain | 7 & above | Turnbuckle | 1000 |

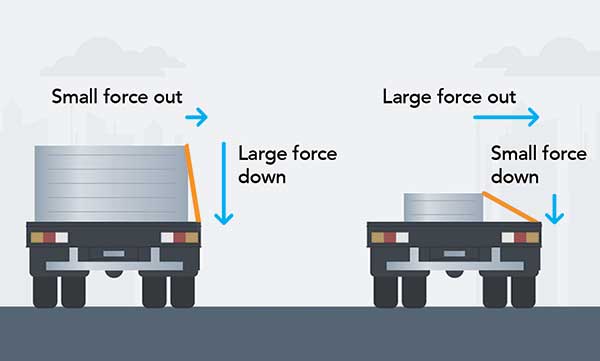

Tie-down lashings are most effective if they are vertical and tight. The more a lashing is angled away from the load, the less the clamping force. This is called the angle effect.

| APPROX ANGLE | ANGLE EFFECT | EFFECTIVENESS (%) |

| 90° | 1.00 | 100 |

| 60° | 0.85 | 85 |

| 45° | 0.70 | 70 |

| 30° | 0.50 | 50 |

| 15° | 0.25 | 25 |

The lower the lashing angle, the more lashings are required to give the same clamping force. One strap at 90° is equivalent to four straps at 15°. Whether or not a load is blocked also affects the number of lashings needed. If a load is blocked using rated equipment, some of the required restraint will be achieved by that equipment.

Direct restraint can be used for most loads. It is beneficial for loads that are difficult to tie down. A load can be directly restrained by attaching, blocking, or containing without any reliance on friction.

Direct lashings are webbing straps, chains or twist locks that attach a load directly onto a vehicle.

Direct lashings are especially suitable for loads with little or no friction between the load and the loading deck, such as:

The required strength of the direct lashing depends on the weight of the load, the number of lashings and their direction. The lashing strength is the lashing capacity or manufacturer's rating, which should be marked on the lashing.

| LASHING (mm) | LASHING CAPACITY (kg) |

| 12 (synthetic rope) | 300 |

| 25 (webbing) | 250/500 |

| 35 (webbing) | 1000/1500 |

| 50 (webbing) | 2000/2500 |

| 75 (webbing) | 5000 |

| CHAIN SIZE (mm) | WITH CLAW or GRAB HOOKS (kg) | WITH GRAB HOOKS or EDGE CONTACT (kg) |

| 6 (G70) | 2300 | 1700 |

| 7.3 (G70) | 3000 | 2300 |

| 8 (G70) | 3800 | 3000 |

| 10 (G70) | 6000 | 4500 |

| 13 (G70) | 9000 | 6700 |

| 13 (G80)* | 10000 | 7500 |

| 16 (G80)* | 16000 | 12000 |

Different hooks have different lashing capacities. Chains that pass over sharp edges have reduced lashing capacity. The total lashing capacity of a chain and hook should be regarded as the lowest-rated value.

Direct lashings must be angled opposite to any expected load movement. For example, the lashing angling down from the back of a car will stop the vehicle from moving forward. When direct lashings are angled at less than 25° from the horizontal and at 45° from the centre line of the vehicle when viewed from above.

A simple rule is to select lashings with a combined lashing capacity of:

A headboard and side/tailgates can block the load from moving horizontally (forwards, backwards or sideways), provided they are strong enough to withstand the forces the Performance Standards indicate.

A load can also be contained within a vehicle where the load is restrained against horizontal movement by the vehicle structure or other parts of the load. Contained, for heavy loads, means simultaneously fully blocked forwards, rearways and sideways.

Check out our Load Restraint Checklist or see the Load Restraint Guide 2018 for recommended restraint methods for particular types of loads. Silverback has an extensive range of load restraint equipment that covers everything from transport chain tie-downs, ratchet straps, ratchet tie-down systems, hooks and truck winches. We also have an extensive range of shoring bars and cargo bars.

For additional details, consult the relevant legislation in your state or contact your local Silverback team.