|

Silverback |

|---|

Your company and teams should be fully versed in the following.

Under this method, friction stops the load from moving forward, sideways and backwards. Friction force comes from the load's weight and the clamping force of tie-down lashings. The weight of the load alone does not provide adequate restraint alone.

For tie-downs to be effective, the load must be in contact with the vehicle throughout its journey. Tie-down lashings clamp the load to the vehicle to maintain friction. Tie-down lashings include straps and chains. These normally pass over the top of a load and are attached to the vehicle on both sides.

Tie-down lashings need to be pre-tensioned to create the clamping force. This is usually done using mechanical tensioners suitable for the lashing you are using.

When a load is tied down and restrained using friction, it must also be restrained vertically to withstand a minimum force of 20% of its weight (i.e. 0.2W); this stops it from shifting upwards (e.g. on rough roads) and keeps the load in contact with the vehicle throughout its journey.

Some loads are unsuitable for tie-down restraint. These include crushable or fragile loads that can be damaged by lashings during tensioning, offset loads (i.e. loads that aren’t positioned along the centreline of the truck) where lashings can loosen if the load shifts sideways, as well as slippery loads because too many lashings are needed to create the necessary clamping force.

The amount of friction between the load and deck surfaces (and any surfaces in between) will affect how much weight each lashing can restrain. The greater the friction, the more weight can be restrained by each tie-down lashing.

Typical friction levels for common loads are outlined below:

The amount of pre-tension (applied force) that can be achieved in a lashing will also affect the lashing capacity. The greater the pre-tension (applied force), the more weight can be restrained by each lashing.

Tie-down lashings need to be pre-tensioned to create the clamping force. This is usually done using mechanical tensioners (Ratchet Tie-Downs) suitable for the lashing you are using.

Typically, the following is achieved:

25 mm Hand ratchet 100 kgf

35 mm Hand ratchet 250 kgf

50 mm Truck winch 300 kgf

50 mm Hand ratchet (push up) 300 kgf. “Standard Ratchet Tiedown”

50 mm Hand ratchet (pull down) 600 kgf. “Reverse Action Ratchet Tiedown”

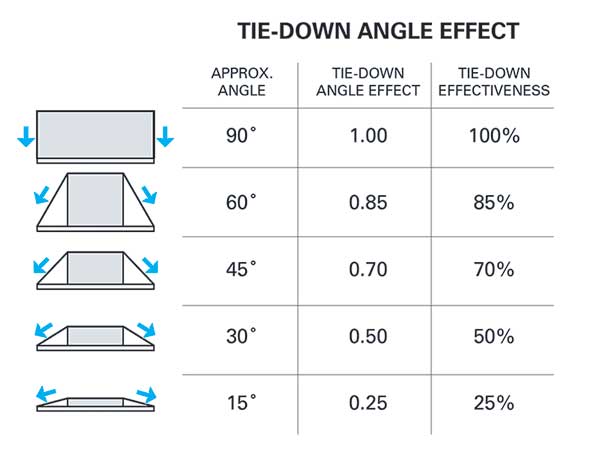

Tie-down lashings are most effective if they are vertical and tight. The more a lashing is angled away from the load, the less the clamping force. This is called the angle effect.

The lower the lashing angle, the more lashings are required to give the same clamping force. One strap at 90° is equivalent to four straps at 15°.

Dunnage is the packing placed under and between parts of the load. Dunnage is generally made from hardwood or softwood timber and is square or rectangular in cross-section.

Dunnage is used to:

HOW TO USE DUNNAGE

Select the size and timber grade/type used for dunnage based on the load and the maximum span between support points. Use rough-sawn hardwood wherever possible.

Limit the use of softwood to situations where:

Do not use softwood for heavy or sharp loads. Dunnage that supports heavy loads on small areas of contact (e.g. large steel sections) should be strong enough to prevent it crushing or splitting. If using materials other than timber that have low levels of friction, coat the dunnage in rubber (or similar) to increase the friction level. Ensure the dunnage is placed to remain as stable as possible. If dunnage is placed directly on the deck, bolt it to the deck or fit it with special stabilising brackets. Always place a rectangular dunnage on its wider face. Do not place dunnage on its narrow face because it can topple over, resulting in a loss of lashing tension and restraint.

When a Heavy Vehicle National Law loading or load restraint offence is proven, each party in the chain of responsibility could be found guilty of committing an offence.